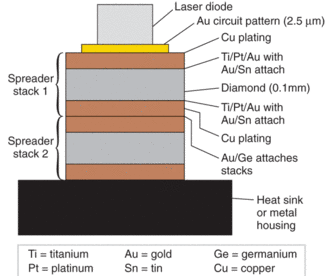

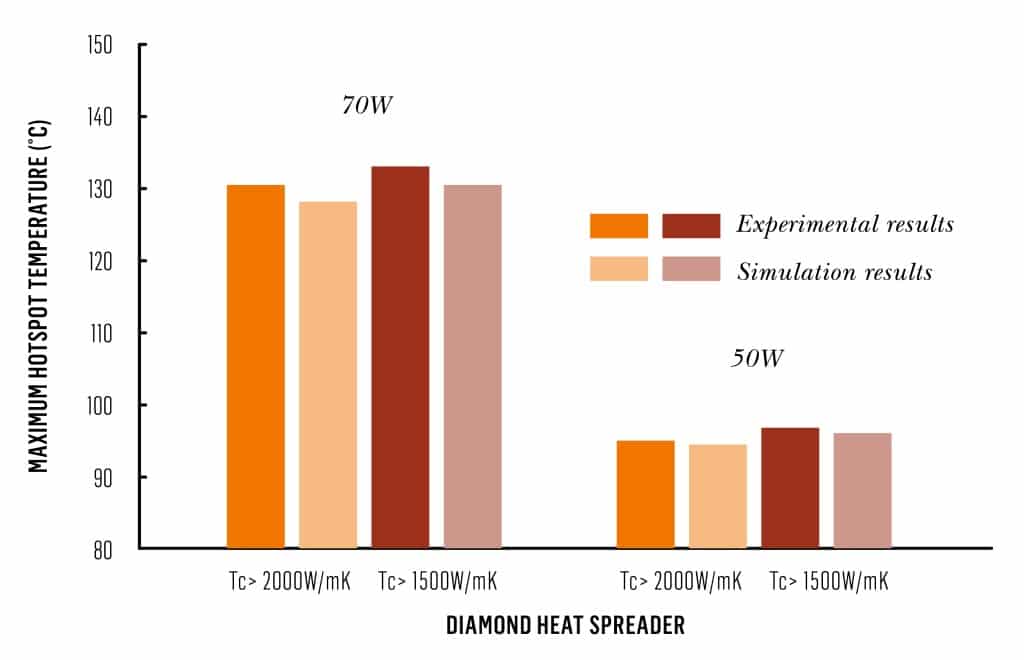

For the chip to dissipate 70w heat power diamond heat spreaders with thermal conductivities of 2000 w m k and 1500 w m k can reduce the maximum hotspot temperature 40 and 38 respectively.

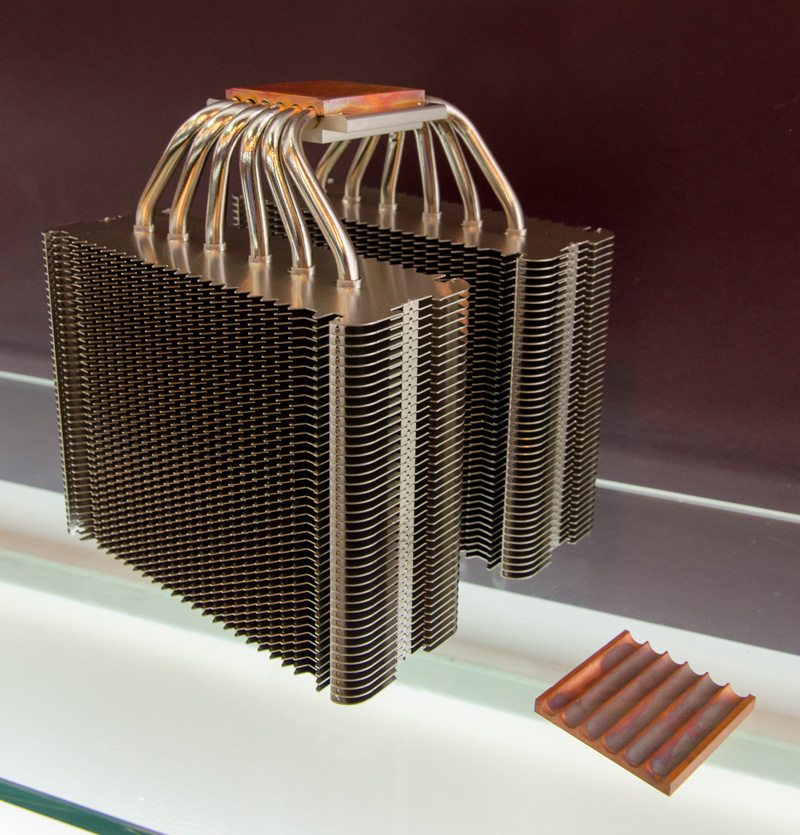

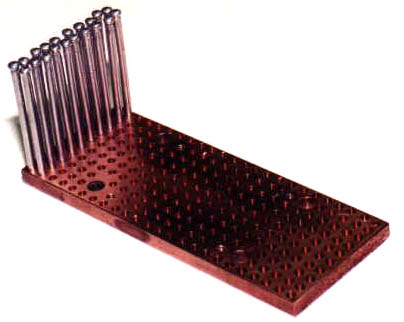

Copper diamond heat sink.

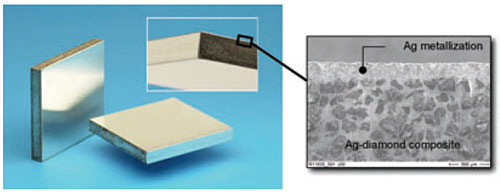

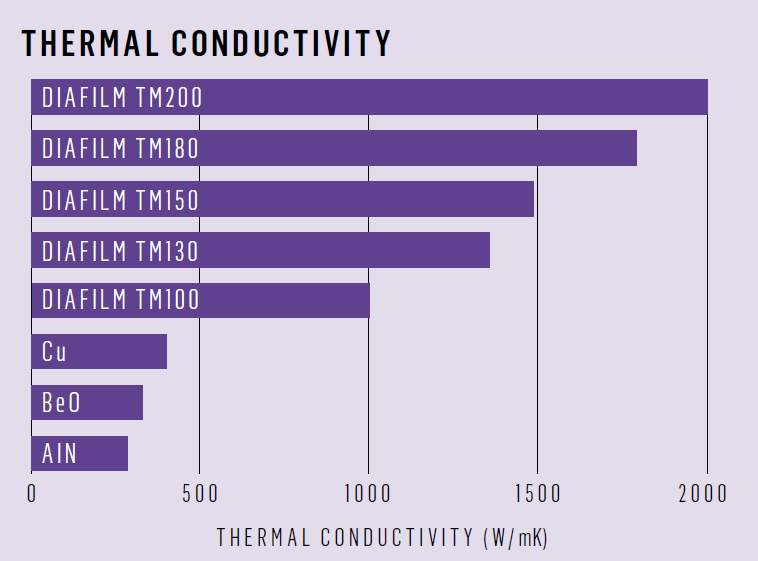

The unsurpassed thermal conductivity of diamond and its high electrical resistivity allow for better performance across virtually.

Applied diamond can build heat spreaders for the most extreme possibilities.

Aluminum silicon carbide.

Cvd diamond heat spreaders and cu heat sinks are crucial components for efficient heat dissipation in high power electronics and photonics.

Since its reorganization in 2001 sumitomo electric u s a.

0 1000 to 0 5000 mm.

It is known from former experiments that there is a very weak bonding between as received diamonds and pure copper matrix in the consolidated composite.

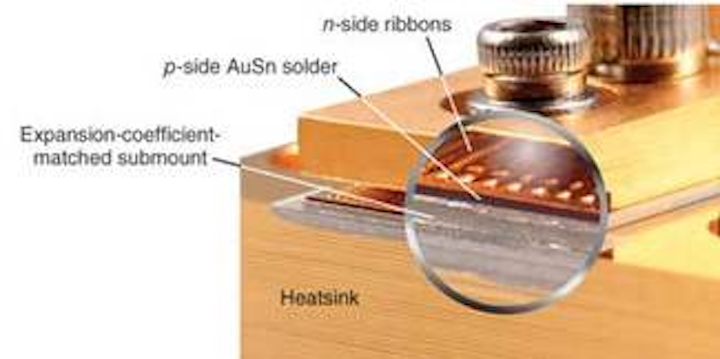

Diamond in any cooling application would be best used as an interface between the source and the dissipation medium this case the heatsink not.

Copper as it has the highest ther mal conductivities in metal has been used for decades as the material of choice as heat sink for semiconductor.

Etched copper and aluminum heatsinks aluminum heatsinks etched up to 080 copper heatsinks etched up to 063 full suite of secondary operations available component side flat heatsinks for printed circuit board pcb assemblies are often used in applications where ambient heat could affect the performance or cause the failure of critical electronic systems.

The ideal material working as heat sink and heat spreader should have a low coefficient of thermal expansion cte and a high thermal conductivity.

As a material diamond has no peer as a semiconductor medium.

Has been a sales and marketing company serving various industries and markets in north america and responsible for new products of sei group companies as well as the following products already in the market.

Copper cu diamond d composites have excellent thermal property but are hard to manufacture with conventional methods.

The ideal material working as heat sink and heat spreader should have a coefficient of thermal expansion cte.

Additive manufacturing am can overcome this issue because of its high.

As heat spreaders and heat sink 1 6.

Copper diamond composites were produced by the powder metallurgical method.

Most fundamental necessities in the development of semiconductor devices is the need to dissipate the large amounts of heat that is generated during operation of such devices.

A 2000 w m k diamond heat spreader can dissipate 110w heating power hotspot heat flux of 10 2kw cm 2 while maintaining the maximum hotspot temperature.