Benefits of side stream and media filtration in cooling towers.

Cooling tower side stream filtration calculation.

This method involves removing particles at a higher rate than accumulation.

For example if the total flow of a system is 1 200 gal min a 400 ton system a sidestream filter with a 120 gal min capacity is specified.

Properly sizing a side stream filtration system is critical to obtain satisfactory filter performance but there is some debate over how to properly size the side stream system.

Determining the proper type for your system includes examining various factors and filter media types.

Various schemes can be implemented.

6 signs your cooling tower requires a side stream filtration consider the following signs your facility requires a side stream filtration system.

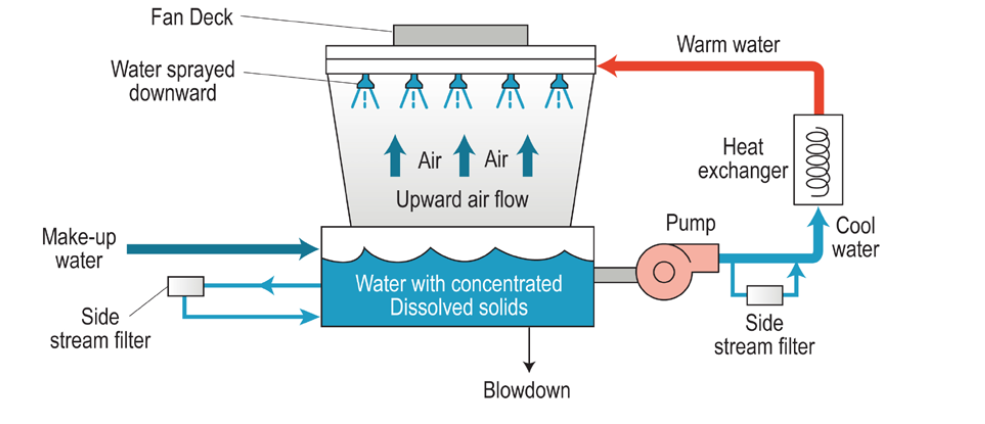

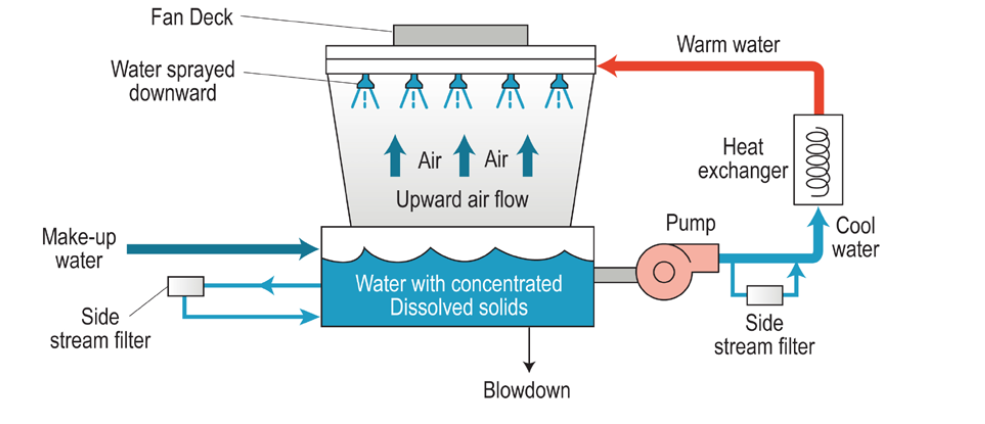

Sidestream filtration as the name suggests refers to the partial filtering of liquid in a system.

The evaluation provides a characterization of side stream filtration technology describes typical applications and details specific types of filtration technology.

Recirculating cooling water systems often experience sludge and solid build up.

System economics are also discussed providing an example project with life cycle.

Many engineers size the system to continuously filter the cooling tower basin water at a rate equivalent to 10 of the total circulation flow rate.

The technology evaluation assesses side stream filtration for cooling towers.

In cooling water systems sidestream filtration is generally sized on 5 10 of the total cooling tower water flow rate.

Side stream filtration is an effective tool for the control of deposition and fouling in a cooling water system.

Due to its outstanding ability to remove submicron particles vortisand filters are especially prized as a pretreatment step for reverse osmosis seawater desalination or ultrapure water production as a side stream filter cooling towers chilled and hot water loops or as a polishing filter after secondary clarifiers or.

What is sidestream filtration.

Cooling tower with side stream filtration examples technology characterization side stream filtration systems continu ously filter a portion of cooling water to remove debris and particles.

Modern day cooling tower systems have thus adopted side stream filtration of the water from the cooling tower.

Choosing the right filtration side stream filtration system can yield significant savings.

The basin water inventory may only be filtered and or side stream filters may be employed at the discharge of the cw recirculation pumps.

Vortisand filters can be used anywhere media filtration is considered.

Filtered water is then pumped back into the main condenser line through a nozzle or re turned to the cooling tower basin called the sump.