Current flow rate and total daily flow up to 63 days which is useful in determining how many times system volume has turned over along with many other.

Cooling tower filtration rate.

Not only do filtration efficiencies improve dramatically but the filters require up to 10 times less backwash water.

Featured in process cooling magazine.

Keep in mind the filtration rate will highly depend on the application and filtration technology at hand.

Cooling tower water filtration and basin cleaning systems lcf filtration systems have a small footprint and are available with flow rates from 11 to 334 m hr 50 to 150 gpm.

Ameriwater high efficiency filters are much more efficient at removing the extremely fine particles that cooling towers scrub from the air.

This method involves removing particles at a higher rate than accumulation.

Over time filtering 1 10 of the cooling loop flow results in the filtration of the total volume of water every 12 72 hours.

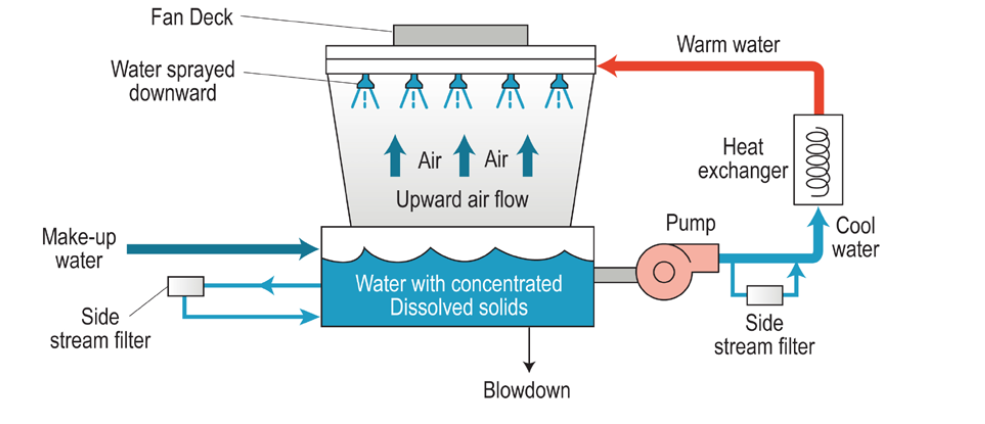

Modern day cooling tower systems have thus adopted side stream filtration of the water from the cooling tower.

Why do cooling towers require filtration.

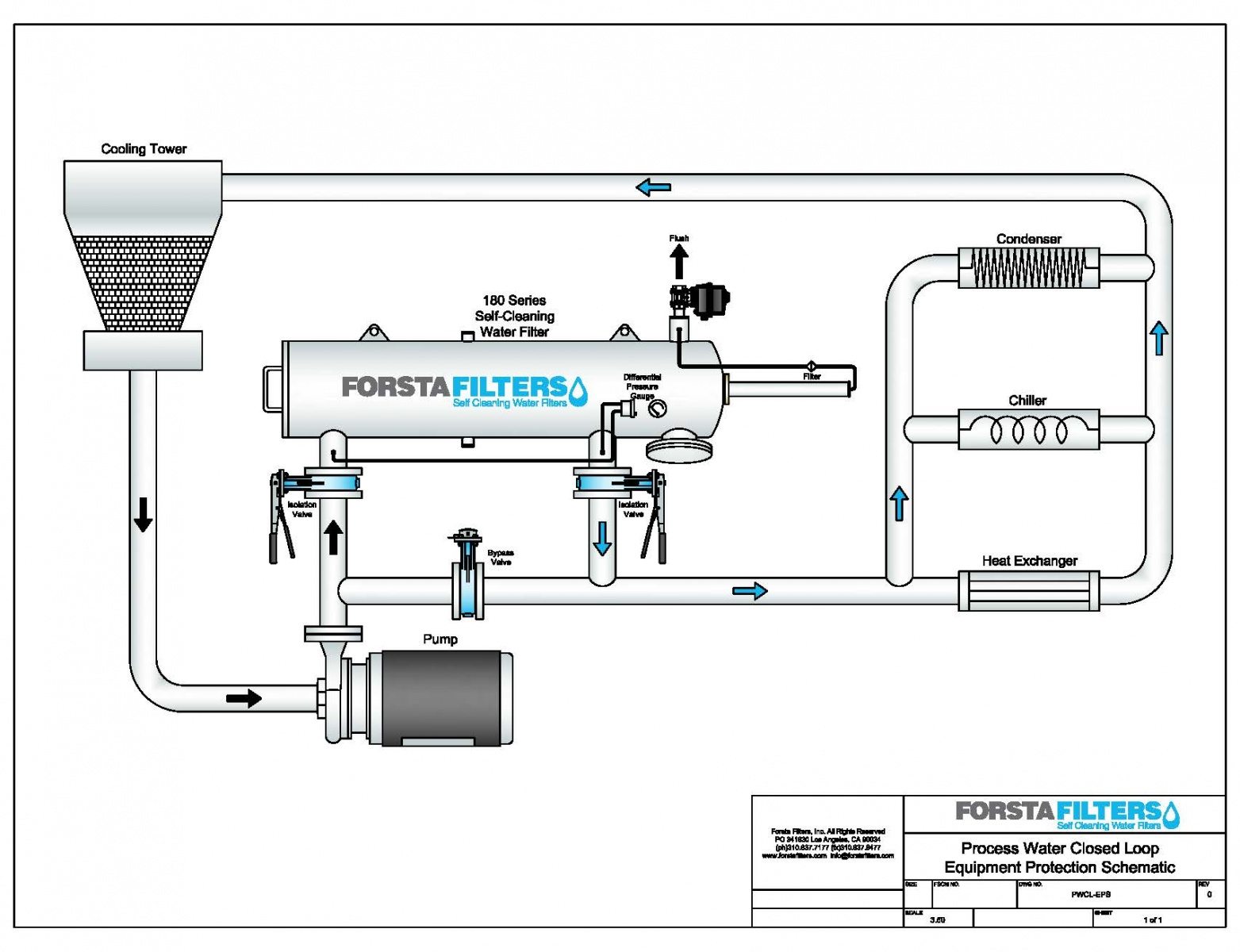

The water is pumped from the cooling tower cold water basin through the side stream filtration system into the heat exchangers and chillers and then returned back to the cooling tower basin.

Low cost vfd plc pump controls multiple cooling tower systems can be kept clean with a single x filtration system at a low pressure and flow rate.

The evaluation provides a characterization of side stream filtration technology describes typical applications and details specific types of filtration technology.

Featured in filtration separation magazine three cooling tower case studies.

Full flow cooling tower filtration drastically reduces heat exchanger and chiller upkeep and improves the overall operation of equipment.

High vol umes of air pass through the tower subjecting compo.

Various schemes can be implemented.

Almost all process cooling systems involve water which over time accumulates dust sand pollen algae and pipe scale particles that originate from cooling towers and makeup water.

An important design criterion is sufficient screen area to handle varying water quality.

Plant engineers discovered that the small 400 gpm side stream four bag filtration system on their 5 300 gpm cooling tower system did not provide the protection they needed for heat exchangers condensers vessel cooling jackets and an 800 ton chiller.

At worst they can degrade system heat transfer capacity and lead to steep increase in dosing rate and consequently the cost of water treatment chemicals e g bactericides.

System economics are also discussed providing an example project with life cycle.