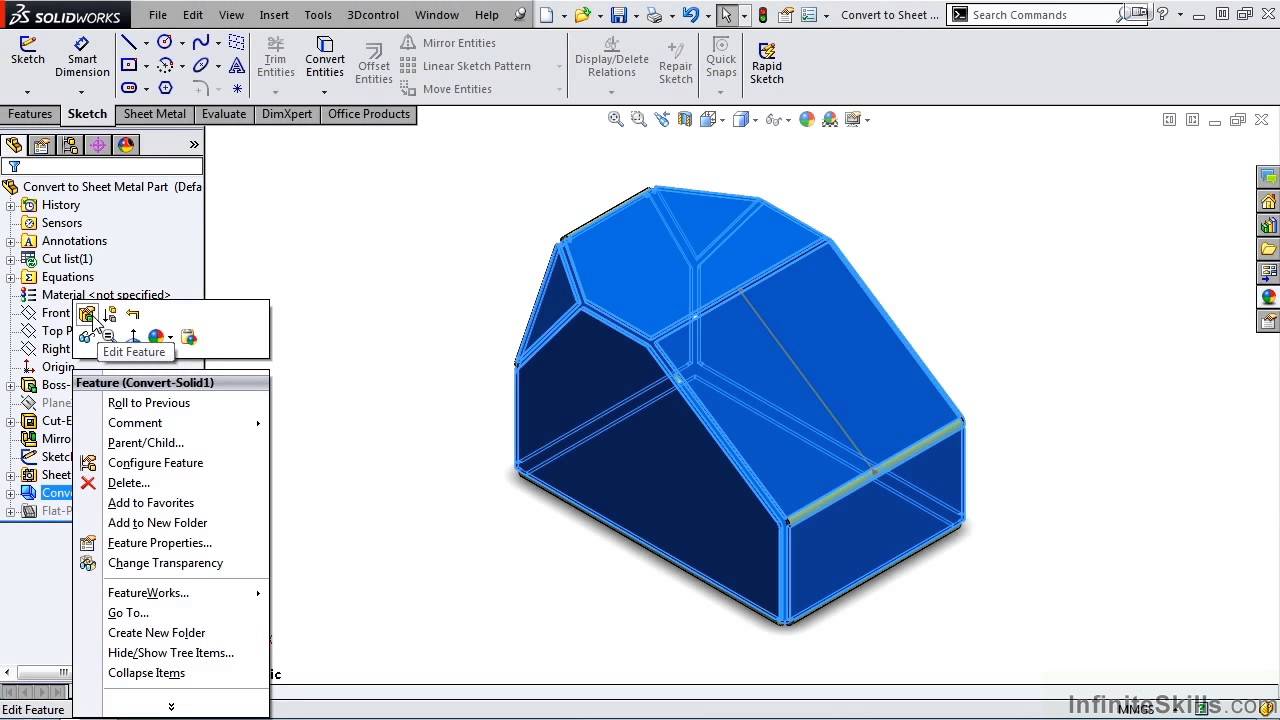

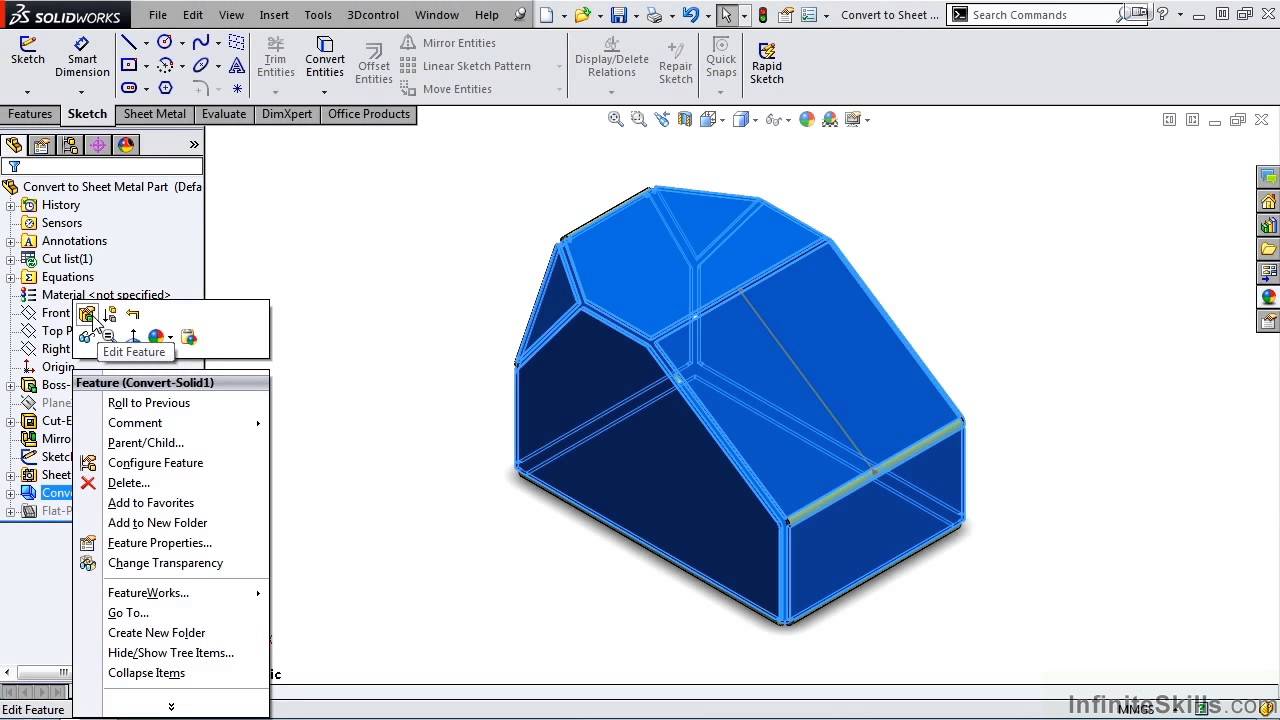

Converting an imported part to a sheet metal part.

Convert to sheet metal solidworks 2018.

You can convert any imported sheet metal type part to a solidworks sheet.

The convert to sheet metal command lets you specify the thickness bends and rips necessary to.

This video shows the difference between creating a sheet metal part from scratch and converting a solid part to sheet metal.

Click convert to sheet metal sheet metal toolbar or insert sheet metal convert to sheet metal.

Convert to sheet metal propertymanager.

Converting a solid part to a sheet metal part.

Click convert to sheet metal sheet metal toolbar or insert sheet metal convert to sheet metal.

Convert to sheet metal tool.

Sheet metal parts are generally used as enclosures for components or to provide support to other components.

If you want to make a cut across a bend drag the rollback bar before the process bends feature in the featuremanager design tree.

Use the convert to sheet metal propertymanager to convert a solid or surface body to a sheet metal part.

Create the solid part.

Extrude the cut through all.

For more information about solid.

In the propertymanager under sheet metal gauges set options if you want to use a gauge table.

Solidworks convert to sheet metal cylinder.

The solid body can be an imported sheet metal part.

To open this propertymanager.

This is a useful tool if the initial part has been created using standard part modeling features such as extrudes and lofts.

You can design a sheet metal part on its own without any references to the parts it will enclose you can design the part in the context of an assembly that contains the enclosed components or you can design the part within another part document in a multibody environment.

Convert to sheet metal convert to sheet metal allows the user to quickly convert parts into sheet metal models from there a flat pattern can be automatically created.

Select use gauge table.

Sketch a closed profile across one of the bends.