554 2 ft 3 20 5 yd 3.

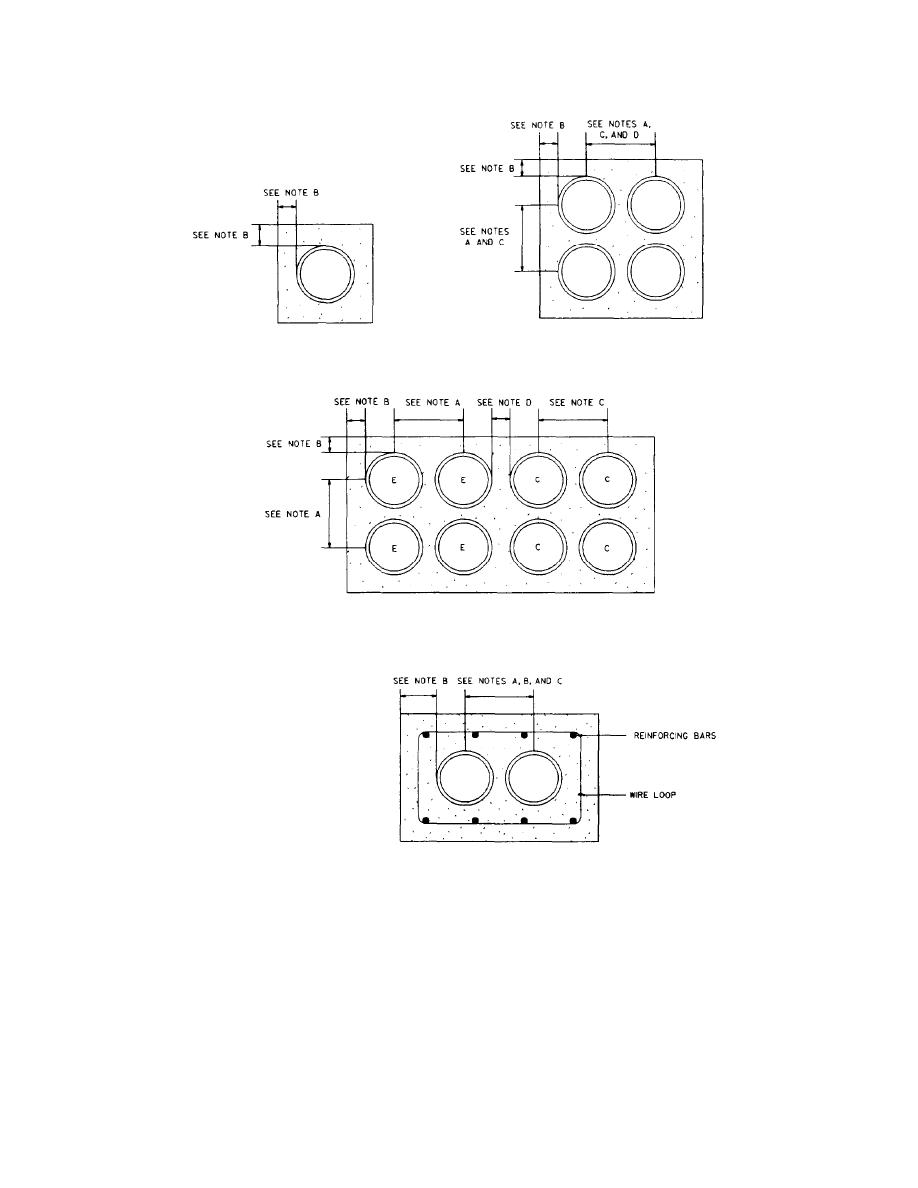

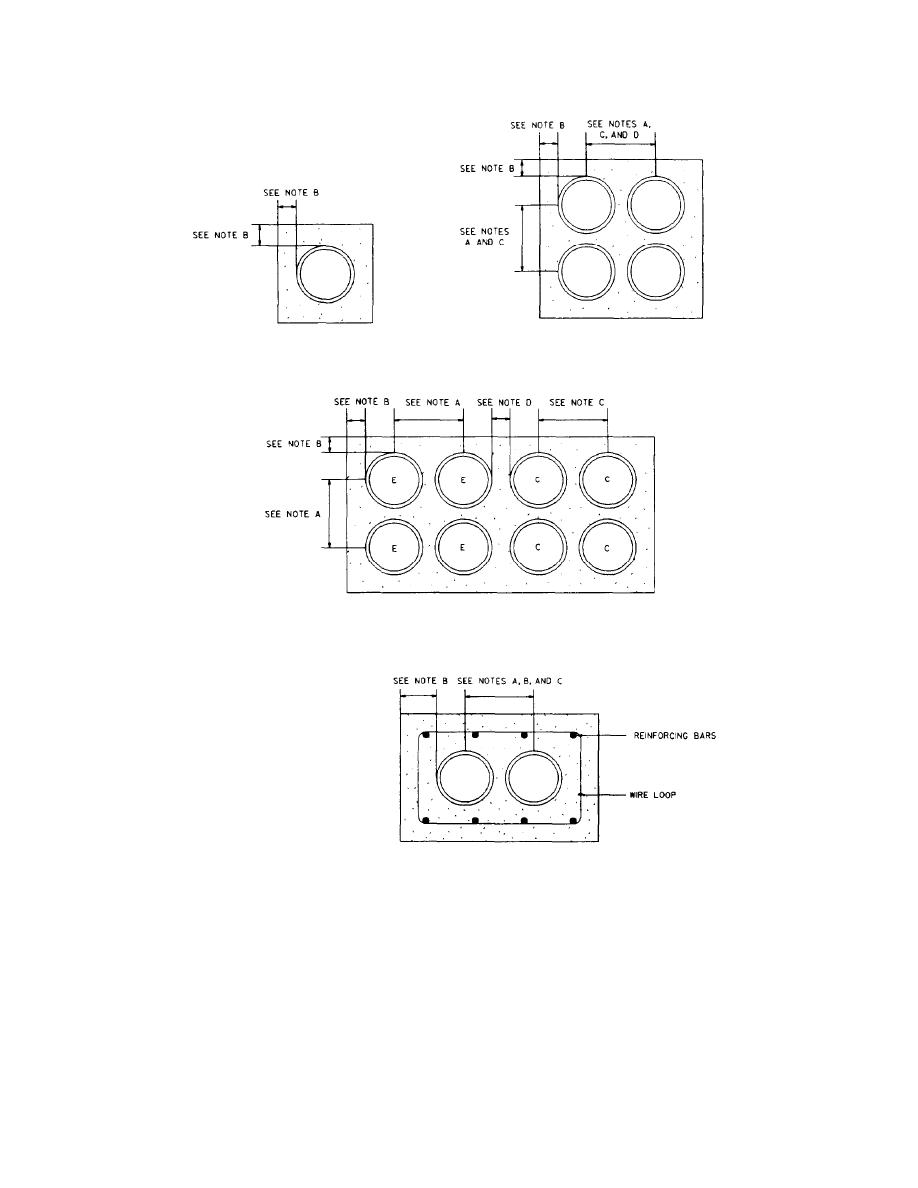

Concrete encased duct bank design.

Concentration of circuits via the same route are planned or expected.

Conduit stub ups shall be rigid steel.

Do not use concrete blocks or other means to support and space conduits that are to receive concrete encasement.

Use walls of trench to form side walls of duct bank where soil is self supporting and concrete.

Underground concrete encased electric conduit duct banks shall consist of type db 60 polyvinyl chloride pvc conduit rated for 90 c cable and meeting nema standard tc 6 and astm f 512 for underground applications.

Cables installed in concrete encased pvc duct this type of system is typically used in urban areas where.

Volume of duct bank.

From gradeto the top of duct bank shall be a minimum of 610 mm 24 inches.

For concrete encased conduits use manufactured pvc spacers and mounts for support and spacing of the conduits.

554 2 ft 3 20 5 yd 3.

Minimum concrete coverage on right.

Concrete encasement shall extend a minimum of 76mm 3 inches from any conduit in the bank to the outside surface.

The top layer of concrete on the duct bank shall be red concrete.

Reinforce concreteencased duct banks where they cross disturbed earth and where indicated.

A metallic backed marking tape shall be installed 12 above all underground conduits and duct banks.

Minimum concrete coverage on left.

Minimum concrete coverage on bottom.

Duct bank width.

Load density is significant.